Tanzania Changes The Rules For African Cacao

Craft chocolate makers are like pirates: always looking out for new treasures.

They are not interested in gold doubloons though. The object of their desire is a flavorful and uncharted fruit. The one found inside tortuous jungles after hours of unpaved streets and wild animals. They are cacao hunters.

Cacao trees can only thrive in tropical climates, specifically 20° north and south the Equator.

Like chocolate consumers, also chocolate makers follow trends.

In a community where knowledge is openly shared, chocolate professionals look at each other. "Where did you get those fabulous cacao beans?", one might ask to the other. Communication flows like in no other food industry and information spreads fast. So it happens that once a place of origin becomes appreciated by a few, then dozens of chocolate bars from that same origin start appearing on the market.

In 2016 the craft chocolate marketplace witnessed the success of Belizean cacao from Maya Mountain Cacao. Renowned for the transparency of its supply chain, Emily Stone's company couldn't keep up with the eager demand.

But chocolate makers are the quintessence of ongoing dissatisfaction. Right after figuring out how to perfect the flavor of Belizean beans, they were already onto a new adventure.

This time it came from an unexpected country of origin: Tanzania, in Africa.

Tanzania’s economy is mostly based on agriculture, employing approximately 80% of the workforce.

The African continent has never really been on the wish list of craft chocolate makers. The poor quality of the cacao grown has always drifted the attention to other exotic destinations. Madagascar being the only exception.Especially in Tanzania, cacao was first introduced in the 1880s by German colonialists. Large commodity companies were the only clients of a quantity-driven market. The extreme focus on quantity over quality never stimulated farmers to grow fine cacao. This always prevented them from earning more money for their product.

Everything changed when two young adventurers decided to break this vicious cycle.Simran Bindra and Brian LoBue were not new to Tanzania. Both working in international development, they found themselves in loco when a serious plan hit their minds.

The idea was to build a facility where to ferment and dry cocoa beans. From local farmers, they would buy "wet cocoa" straight out of the pods, then process it the right way in their center. Cocoa farmers would get paid more than if they were to ferment and dry the beans themselves. The saved time could be spent in bettering farming practices.

In the meantime, the quality of Tanzanian cacao would improve, becoming the object of desire for well-paying craft chocolate makers and chocolatiers. They would call their enterprise KOKOA KAMILI.

The dream became a reality in the Kilombero Valley. Here is where fine cacao arrives daily from 2,500 local farmers and 30+ staff members (employed locally) take care of the fermenting and drying operations.The chain of missed opportunities for Tanzanian cocoa farmers has finally been broken.

If this sounds like easy business, it's because you never had to face the rural setting of Tanzania.

Simran and Brian live with their families in the main city and port of Dar es Salaam, 500km from their facility in the Kilombero Valley. The journey is long and difficult.

Simran reveals:

"One of our biggest challenges when we started (and still today) is the remoteness of our operation.

We are only 500km from the main city and port of Dar es Salaam, but the journey can take anywhere from 10 hours to a few days during the rainy season.

The last stretch of the road can get pretty muddy during the rains and so trucks get stuck, bridges wash out, and water levels can sometimes make some stretches impassable. It's not all bad though - we do get to drive through a game park and see elephants, giraffes and zebras from the road!".

Also Brian keeps a positive attitude towards the difficulties of such business:

"Our facility is totally off the electrical grid and the mobile communications are pretty spotty, which makes it even more difficult to stay connected with family. However, when my family does come with me out to Kilombero, we have an amazing time exactly because of the remoteness.

My children attend the kindergarten run by a nearby convent, and spend afternoons playing soccer with children at a local orphanage. On weekends we ride bicycles on meandering paths through the village and take quick jaunts into the nearby Udzungwa National Park for dips in the river.

"The distance never discouraged them.

Since they can't visit the fermentary every day, the success of their operations comes from having employed the best people in the area.

Systems were built to enable the staff to do the physically stressful jobs of fermenting and drying cocoa as easily and consistently as possible. Some examples are distributed palletization of micro-lots and stackable tables made with the lightest wood available.

Simran admits: "Our team really is the "special sauce"- without them we'd be in a lot of troubles.

"A strict control on quality is another key factor in the success of Kokoa Kamili.

Traceability and quality control systems were implemented from day one.

Simran explains:

"We have pretty strict protocols that we follow and track (the Excel sheet we use is a real beast) to make sure that everything in every day's fermentation is going according to plan. We also are pretty strict with sorting our beans and have a systematic blending process to ensure that every bag of beans in a shipment is exactly the same as every other".

Brian adds:

“Every morning our staff of 30+ people gather to talk about Quality issues from the day before. If farmers are harvesting fruit too early, or if we're drying cocoa too quickly, or if the organic protocols need to be tweaked to better preserve purity. And Quality doesn't just apply to the cocoa.

Are the vehicles running properly? Are other buyers raising their price so we should raise ours?

It's a team event, which is open for everyone to criticize and suggest improvements for any part of the business.”

This attention to quality brought to a growing appreciation for Kokoa Kamili beans.

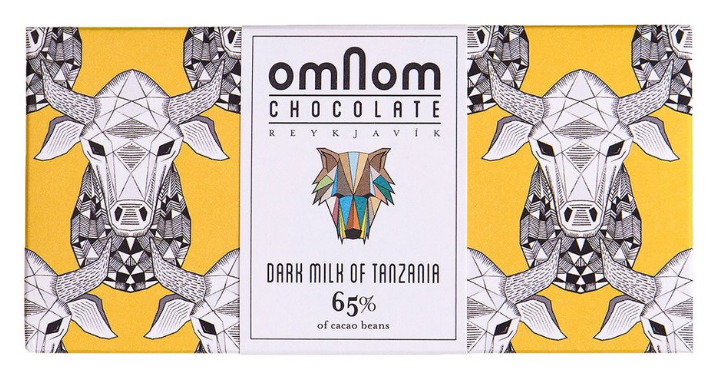

The majority of their customers is high-end chocolate makers. Their first clients were Chocolate Naive from Lithuania and Mast Brothers from the US, but their client base is expanding daily. It now includes renowned craft makers like Dandelion Chocolate, Letterpress Chocolate and the Iceland-based Omnom Chocolate.

Chocolate maker Kjartan started using Kokoa Kamili beans as part of Omnom collection around March this year:

"We first heard about them through Gino from Meridian Cacao and got some samples from them, for our first test samples.

What really struck me with its flavour was its rich earthiness and dark berries, hints of plums and pears. It lends itself nicely as a dark milk chocolate as well. I also liked it a lot because it has proven to be our go-to chocolate when we need something that has a rich chocolate flavour".

Thanks to the determination and transparency of Simran and Brian, now also Africa can begin the journey in becoming an appreciated place of origin for fine cacao.

What craft chocolate bars made with Tanzanian cacao have you tried?